Micro Shearing

|

Dieless Punching of Ultrasmall-Diameter Holes |

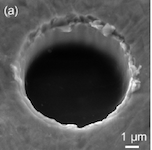

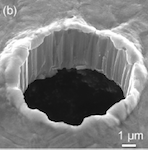

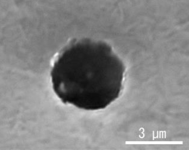

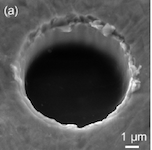

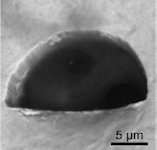

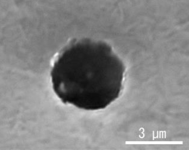

| The dieless punching of ultrasmall-diameter holes was attempted because it is difficult to punch such holes by conventional punching methods. As a result, a hole with a diameter smaller than 6 µm was punched in a 3 µm-thick stainless-steel sheet. Paper Paper (KIT only) (Precision Engineering, Vol.78, 2022, pp.114-123) |  |  | | Puched hole (entrance) | Puched hole (exit) |

|

Dieless Blanking using Noncylindrical Micropunches |

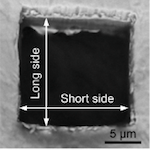

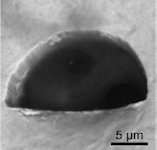

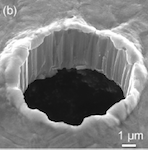

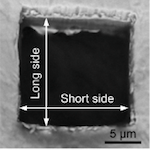

| Piercing holes using noncylindrical micropunches was attempted by dieless blanking. Square and semicircular microholes were successfully pierced in a stainless-steel sheet. Paper Paper (KIT only) (Precision Engineering, Vol.83, 2023, pp.250-261) |  |  | | Square microhole | Semicircular microhole |

|

Examination of Backing Material and Punch Shape in Dieless Punching of Microholes |

| In the dieless punching of microholes, the backing material was changed from adhesive tape to a sticky note. Additionally, a stepped punch with a shorter straight section was employed. As a result, a microhole with a diameter of less than 4 µm was successfully punched. Paper (Procedia CIRP, Vol.137, 2025, pp.13-18) |  | | Microhole less than 4 µm in diameter |

|