Micro USM (Ultrasonic Machining)

|

Ultrasonic Machining of Micropins |

| The fabrication of convex shapes by micro USM was performed. A cemented tungsten carbide micropin of 5 Ám diameter was successfully machined. The machined surface can be smooth and glossy. Paper (Journal of the Japan Society for Abrasive Technology, Vol.50, No.11, 2006, pp.649-653) |  | | Fabricated micropin of 5 Ám diameter |

|

Microultrasonic Machining by the Application of Workpiece Vibration |

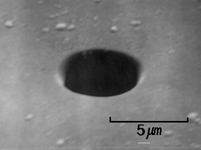

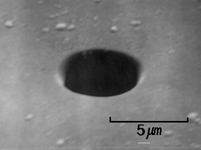

| In order to obtain high-precision tool rotation, a spindle mechanism employed in micro-EDM machines was introduced. Since the mechanism does not allow the vibration of tools, the workpiece was vibrated. As a result, microholes of 5 Ám diameter were successfully drilled. These holes have the smallest reported diameter for holes drilled by USM. Paper Paper (KIT only) (Annals of the CIRP, Vol.48, No.1, 1999, pp.131-134) |  |  | | Drilled microhole of 5 Ám diameter | 48 holes drilled with single PCD tool |

|

Application of USM to Micromachining by On-The-Machine Tool Fabrication |

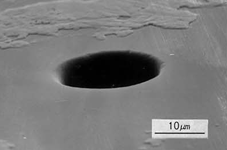

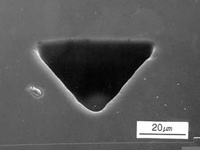

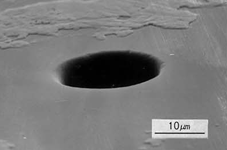

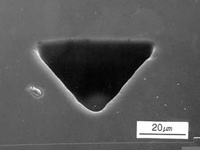

| A technique of micro USM by applying on-the-machine tool fabrication by EDM was proposed. Microholes of 20 Ám diameter were drilled in silicon. Noncircular microholes were also fabricated. Paper (International Journal of Electrical Machining, No.2, 1997, pp.31-36) |  |  | | Microhole of 20 Ám diameter | Triangular microhole |

|

Microultrasonic Machining Using Multitools |

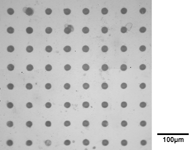

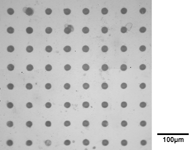

| Micro USM with a single tool is time-consuming. In this study, multitools were fabricated and then used in the machining of arrays of microholes. The drilling time per hole was greatly reduced. Paper (Proceedings of The 7th International Conference on Progress of Machining Technology, 2004, pp.297-301) |  |  | | Multitool | Arrays of microholes drilled |

|

Study on Material Removal Mechanism in Microultrasonic Machining |

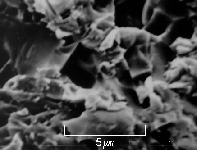

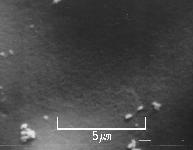

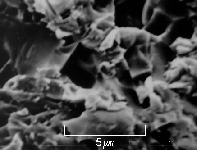

| No sharp edges caused by brittle fracture are observed on surfaces processed by micro USM. It is probable that the material removal mechanism in micro USM is based on ductile fracture, not on brittle fracture as in conventional USM. Paper (Proceedings of The 5th International Conference on Progress of Machining Technology, 2000, pp.739-743) |  |  | | Surface processed by micro USM | Surface processed by conventional USM |

|