Micro Grinding

|

Drilling of Microholes in Glass by Ultrasonic Grinding Using Ultrasmall-Diameter Tools |

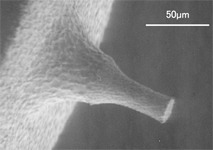

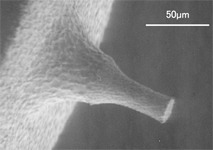

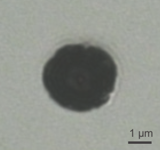

| The drilling of microholes with a diameter smaller than 0.1 mm by grinding, which has not been reported previously, was attempted. Cemented tungsten carbide micropins were fabricated by electrical discharge machining and used as grinding tools. As a result, the drilling of 30-Ám-diameter microholes in crown glass was successfully carried out. Paper (Journal of Japan Society for Abrasive Technology, Vol.57, No.2, 2013, pp.102-105) |  |  | | Ultrasmall-diameter tool | Drilled hole |

|

Drilling of Microholes Down to 10 Ám in Diameter Using Ultrasonic Grinding |

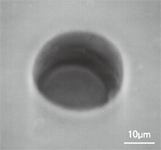

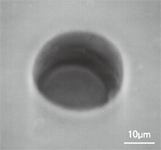

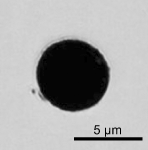

| The drilling of microholes was attempted in crown glass by ultrasonic grinding. Micropins were fabricated by electrical discharge machining and then used as the micro-grinding tools. As a result, the drilling of a microhole 10 Ám in diameter was successfully achieved. Paper Paper (KIT only) (Precision Engineering, Vol.38, No.3, 2014, pp.605-610) |  | | Drilled hole 10 Ám in diameter |

|

Drilling of Microholes Less Than 5 Ám in Diameter Using Ultrasonic Grinding |

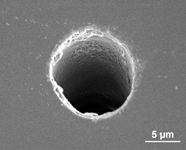

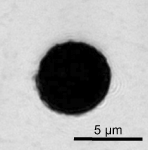

| The drilling conditions to prevent chippings and cracks on the hole edge were experimentally determined and then employed for the drilling of microholes less than 5 Ám in diameter. As a result, a microhole as small as 3.2 Ám in diameter was successfully drilled in crown glass using a cemented WC microtool. This is the smallest-diameter hole drilled by grinding. Paper (International Journal of Automation Technology, Vol.18, No.2, 2024, pp.161-168) |  | | Drilled hole 3.2 Ám in diameter |

|

Drilling of Microholes Using PCD tools by Ultrasonic Grinding |

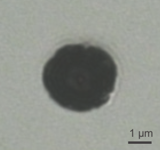

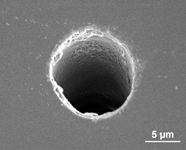

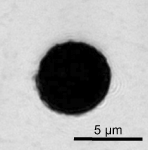

| The ultrasonic grinding of microholes was performed using sintered diamond (PCD) with extremely high wear resistance as the tool material. As a result, microholes 5.5 Ám in diameter were drilled in hard and brittle materials such as crown glass and monocrystalline silicon. Paper Paper (KIT only) (Proceedings of JSME 2020 Conference on Leading Edge Manufacturing/Materials and Processing (LEMP 2020), 2020, V001T08A010) |  |  | | Microhole drilled in silicon | Microhole drilled in crown glass |

|